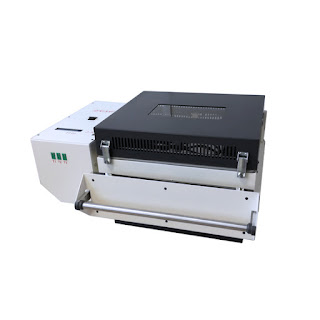

Get reflow ovens at Best price through online at Singapore

Maximum more moderen-fashion reflow ovens, referred to as the pressured convection kind, offer warmth by means of blowing warmed air on and round assemblies. One of the benefits of this form of oven is that these are able to provide warmness to an assembly step by step and uniformly, specific of component colour or texture. Even though the absorption of this warmness may also vary barely because of the varying thickness and factor populace of an assembly, more moderen style. ovens normally provide heat in such a manner in order that the Δt isn't large. Further, the most temperature and temperature fee of a given profile may be controlled strictly with those ovens.

That is, those ovens provide in onlin price of reflow oven more area to zone balance, which offers the operators of these ovens with a extra controlled reflow technique. While used on forums containing a mix of smt and plated through-hole (pth) components, thru-hole reflow, while doable by way of particularly modified paste stencils, may allow for the wave soldering step to be eliminated from the meeting procedure, doubtlessly reducing meeting charges. Even as this will be said of lead-tin solder pastes used previously, lead-free solder alloys inclusive of sac present a assignment in phrases of the limits of oven temperature profile adjustment and requirements of specialized via-hole additives that need to be hand soldered with solder twine or cannot reasonably resist the high temperatures directed at circuit boards as they journey on the conveyor of the reflow oven.

The reflow soldering of via-hole additives the usage of solder paste in a convection oven manner is known as intrusive soldering. The aim of the reflow technique is for the solder paste to attain the eutectic temperature at which the specific solder alloy undergoes a segment trade to a liquid or molten country. At this specific temperature range, the molten alloy demonstrates residences of adhesion. Molten solder alloy behaves an awful lot as water, with homes of concord and adhesion. With sufficient flux, inside the state of liquidus, molten solder alloys will exhibit a characteristic known as "wetting." wetting is a assets of the alloy whilst inside its specific eutectic temperature range. Wetting is a necessary condition for the formation of solder joints that meet the standards as "perfect" or "goal" situations, at the same time as "non-conforming" is taken into consideration faulty in keeping with ipc.

The reflow oven temperature profile is suited for traits of a particular circuit board assembly, the dimensions and depth of the floor aircraft layer within the board, the wide variety of layers inside the board, the number and size of the additives, for instance. The temperature profile for a selected circuit board will allow for reflow of solder onto the adjacent surfaces, without overheating and negative the electrical additives beyond their temperature tolerance. Within the traditional reflow soldering manner by onlin price of reflow oven, there are usually four ranges, referred to as "zones", every having a awesome thermal profile: preheat, thermal soak (frequently shortened to just soak), reflow, and cooling. read more...

Comments

Post a Comment